The power of innovation - progress in every solution

How do I make my applications fit for the latest requirements?Voltage levels are rising, power densities are increasing, winding technologies are changing and material requirements are becoming more complex. Making applications fit for future conditions requires more than just meeting specifications - it requires development expertise. This is precisely where it becomes clear whether your wire supplier is also your development partner of tomorrow.

Talk to SHWire about your project

Table of contents:

Is your wire supplier also your development partner of tomorrow?

Depth of research - right down to the coating chemistry

Three development directions. One goal: series production capability

Innovations don't end in the laboratory - they start in series production

Proof of our innovative strength

Your next step

Whether a supplier can really support development work is not determined by individual product innovations or whether they can deliver to specification today. The decisive factor is whether he supports technological development steps in the long term and actively supports them.

An innovative partner can be recognized by the fact that it understands trends at an early stage, masters physical and chemical mechanisms of action in detail, develops new solutions in a structured manner and transfers these reproducibly into stable series processes.

At SHWire, innovative strength means systematically leading progress - from mastering coating chemistry to reproducible industrial series solutions.

"F" in R&D means depth of research.

Right down to paint chemistry.

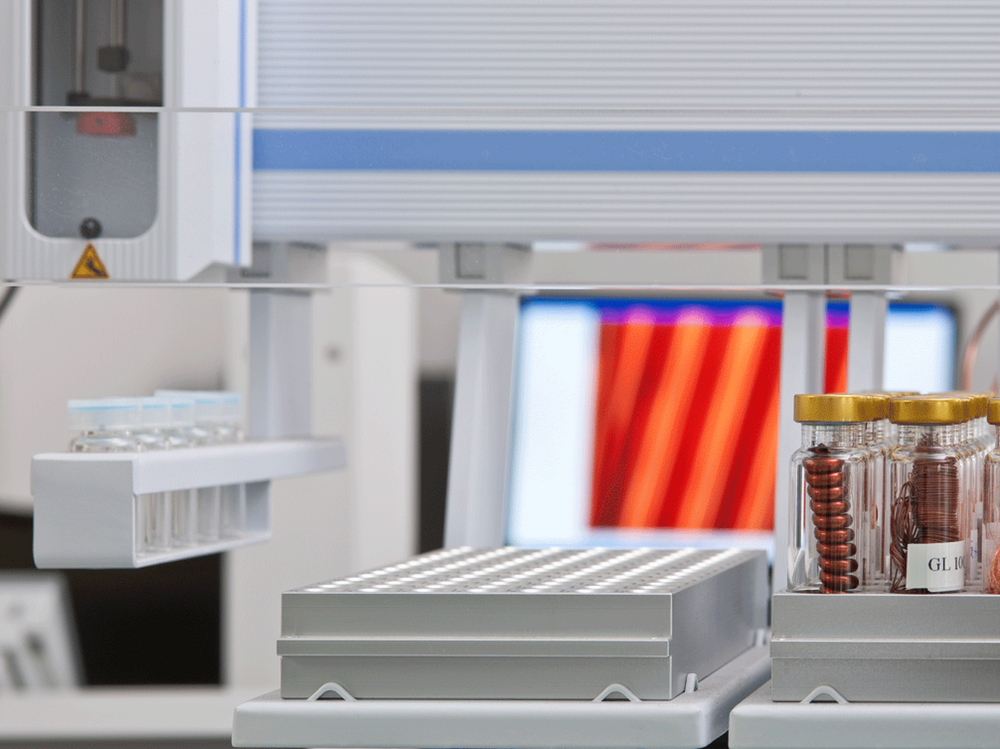

Many people can produce wire. We know the chemistry behind it. Our research and development structure is deeply integrated - with our own coating chemistry, synthesis, analytics and experimental diagnostics.

Three laboratory areas form the foundation:

Synthesis laboratory

In-house development and production of paint components.

Chemical analysis laboratory

In-depth investigation of material properties and interactions.

Partial discharge diagnostics (PD laboratory)

Experimental protection for the highest electrical loads.

For us, innovation does not start with the data sheet, but with molecules, layer mechanisms and interactions in the electrical insulation system. Using clearly defined design-of-experiments (DoE) principles, we systematically vary parameters, make cause-and-effect relationships visible and create reproducible findings. The result is not trial-and-error development, but reliable, reproducible solutions.

Three development directions. One goal: series production capability

R&D projects can follow three different development paths:

1. customer-induced development

We jointly develop solutions for your applications. Coating systems, wire design, drawing-in behavior, winding process and motor function are coordinated until the overall system functions stably.

2. market pull

We pick up on technological developments at an early stage, for example increasing tension requirements, new winding concepts or changed media conditions - and develop solutions before they are absolutely necessary.

3. technology push

We provide impetus based on our own convictions: new coating formulations, new layer designs and new material combinations. Not as an end in itself, but to specifically push physical and chemical boundaries.

The result for you:

- Lower risk thanks to our advance performance

- Faster time to market for your products

- Secure technological roadmaps

Innovations don't end in the lab - they start in series production

An innovation only has value if it works in practice. That is why we consistently transfer every development into stable, reproducible series processes:

- clearly defined parameter windows

- tight tolerance control

- robust layer structures

- assured process capability

For us, reproducibility is not a result, but a principle.

Evidence of our innovative strength

Innovation at SHWire is visible - in solutions ready for series production:

SHXLife®

New benchmark in partial discharge resistance for applications with increased voltage requirements.

PI wires

Maximum chemical, thermal and partial discharge resistance for demanding industrial environments.

SHTherm® 220 Flat

Uniform layer thicknesses >150 µm as the basis for modern flat wire and hairpin concepts.

XXX

i.a. Iasdasd

SHGlide®

Self-developed bonded coating formulation for higher winding speeds and reduced system load.

YYYY

Vasdsad

At SHWire, the power of innovation means systematically leading our customers' technological progress - from mastering coating chemistry to reproducible industrial series solutions.

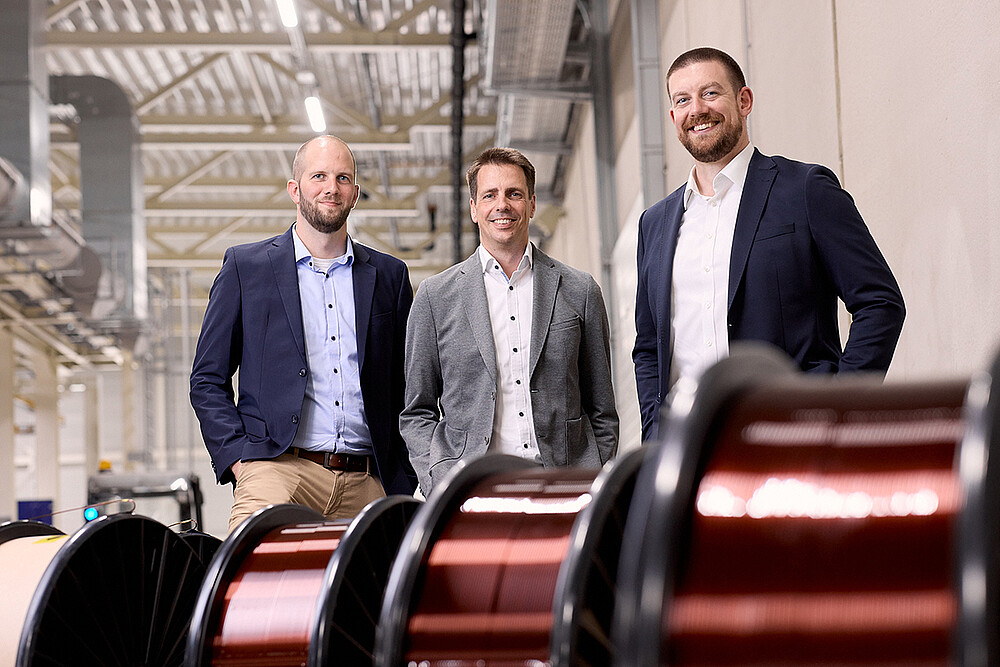

Dr. Andreas Levermann, Managing Director SHWire

Get in touch with us!

Whether you have a specific winding task, a high-voltage project or questions about supply chain management - we will put you in touch with the right contact person.

Write to us using the contact form or contact our sales team directly. We will get back to you promptly with a proposal for the next steps.

Email to sales@sh-wire.de Call +49 (0) 5281 9880

- Technical questions (system, innovation, quality)

- Questions about supply chain, availability & conditions

- Strategic projects & long-term partnerships

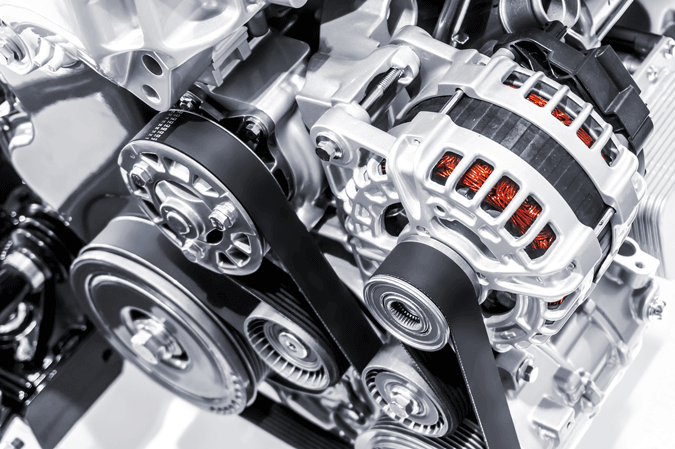

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

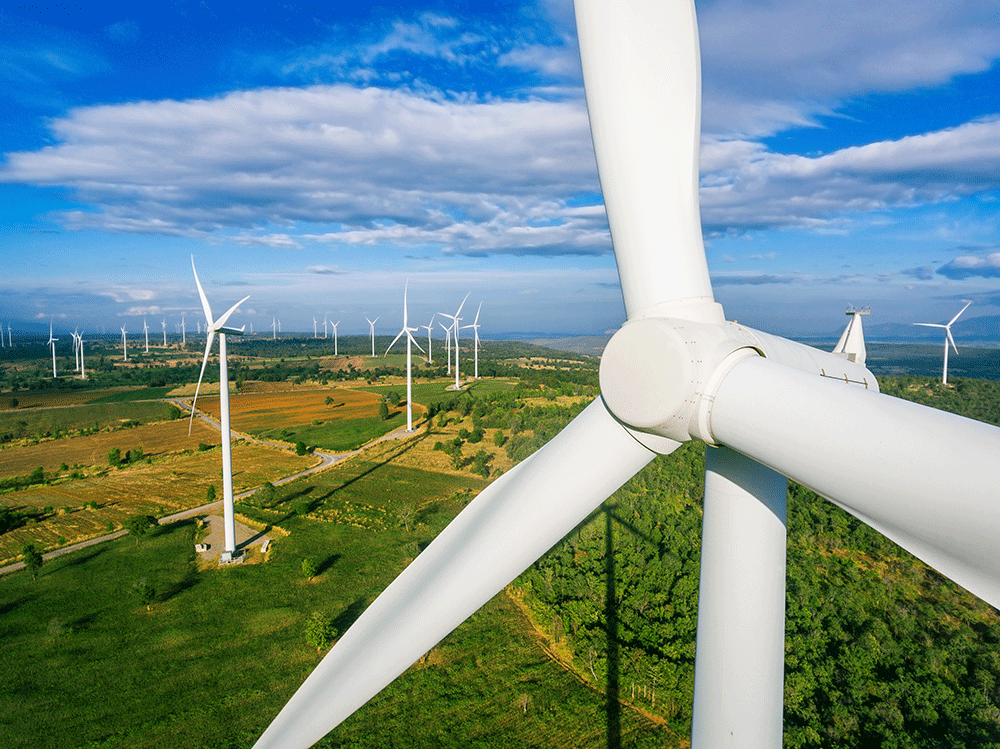

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)