Modern Solutions for Energy Transmission

Enamelled Wires for modern Energy Systems

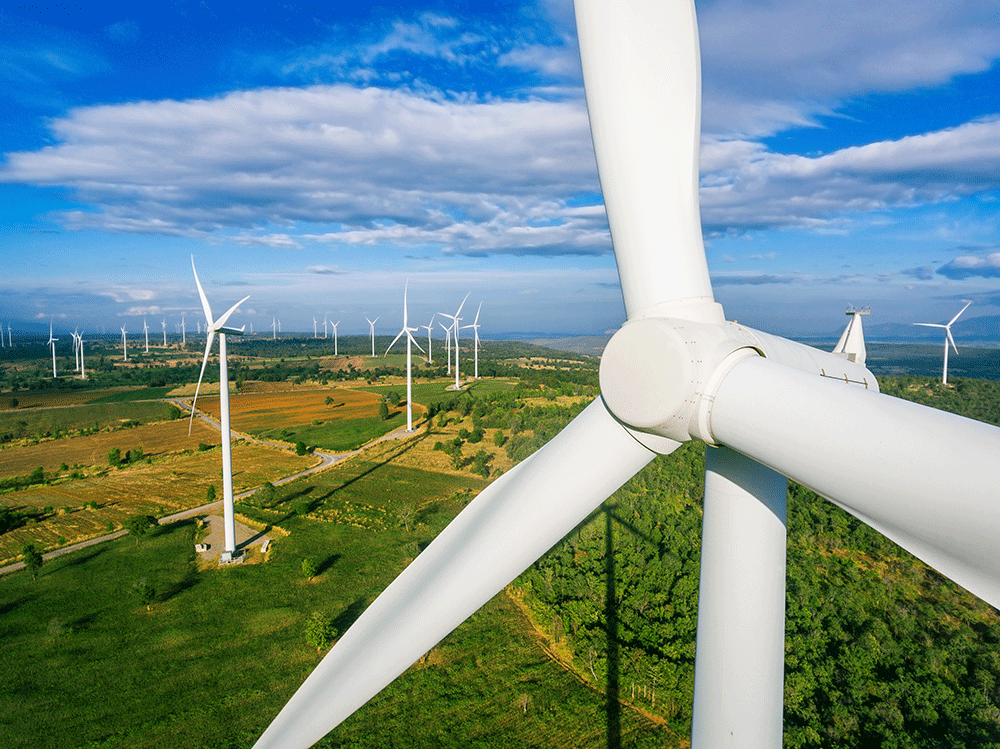

Together with our customers, we develop innovative solutions for the challenges of energy suppliers - and have been doing so for over 70 years. In most cases, energy is not generated in close proximity to the end consumer. It often has to be transported over long distances, for example from offshore wind farms inland. Our formable and durable enamelled copper and aluminium wires are designed for the construction of distribution and power transformers.

Quality Management

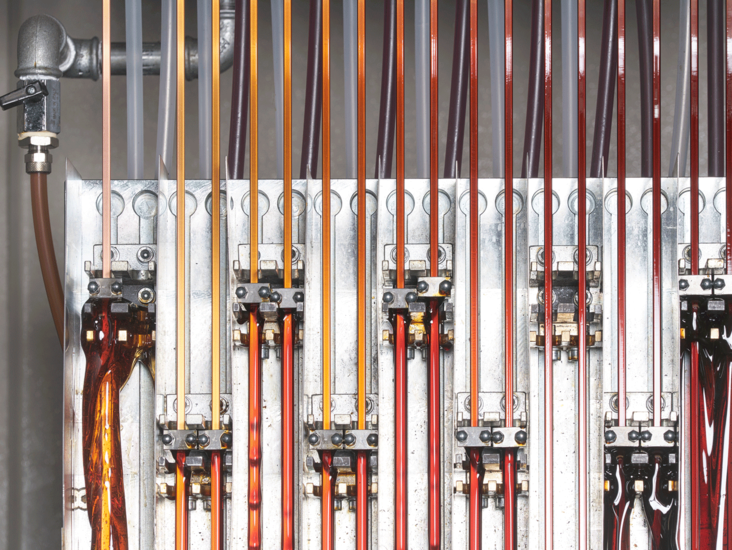

With our innovative process monitoring, we are taking a further step towards Industry 4.0. In order to guarantee the high quality of our products, we permanently record all operating and machine data for each machine and production line. All quality-relevant process and production parameters are seamlessly measured, controlled, documented and stored. This is done fully automatically throughout the entire production process. Should problems arise during operation, we recognize them immediately and intervene to regulate them.

Our enamelled wires for energy transmission

SHTherm® 210

- High temperature resistant enamelled copper wire,

round, temperature class N - Excellent mechanical resistance to abrasion

- Extremely low coefficient of friction for gentle

wire processing - Verifiably improved strength of insulation

SHTherm® 210 Alu

- High temperature resistant enamelled aluminium wire,

round, temperature class N - Excellent resistance to chemical stress

- Best processing properties due to optional,

additional lubricating coat

SHTherm® 210 Flat

- High temperature resistant enamelled copper wire,

flat, temperature class N - Excellent thermal long-term resistance and overload capacity

- Excellent resistance to mechanical stress

- Excellent insulation properties

In addition to our standard products, our development team is happy to work with you on projects to tailor our wire to your needs. This is how we jointly drive innovation forward. Feel free to contact us for development projects.

Our Know-how – Your Benefits

- More than 70 years of experience in enamelled wire production

- Fast decisions even for large projects

- Short reaction times for short-term requirements

- Customer-specific new developments possible

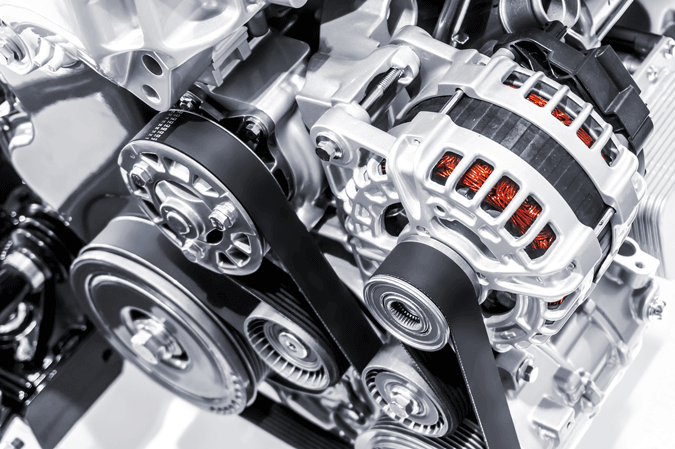

The standard for QM systems in the automotive industry IATF 16949:2016 defines the sector-specific requirements for series and spare parts production based on DIN EN ISO 9001:2015.

In the course of the annual certification SHWire has successfully passed the surveillance audit by the certification company DQS. For this purpose, processes of the QM system are continuously questioned, monitored, evaluated and optimized by the employees. Customer satisfaction is optimized by the continuous improvement of system and process quality. This enables us to meet the increasing demands on product quality, productivity and competitiveness and also to increase the performance for our customers.

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)