System expertise - solution at every step

Who can help me when I need more than just a wire, but a solution?Electrical, thermal, mechanical, chemical and process-related requirements interact in modern drives, motors and systems - and together they determine function, efficiency and service life.

This is precisely where SHWire's system expertise steps in.

We record these requirements in a structured manner, translate them methodically into resilient wire and system solutions and accompany applications from the initial idea through to series production - reproducible, reliant and predictable.

Talk to SHWire about your project

How to recognize system competence

For us, real expertise does not start with the large system, but with the smallest detail: the enameled wire itself.

We know every layer, micrometer and material behavior under actual operating conditions.

We understand how different influences interact in real applications:

- thermal stresses

- electrical field effects

- mechanical loads

- chemical influences (media, resins, environment)

- Partial discharge behavior

- Winding processes and automation

This knowledge forms the basis for system solutions that function reliably in motors, actuators, transformers or high-voltage systems.

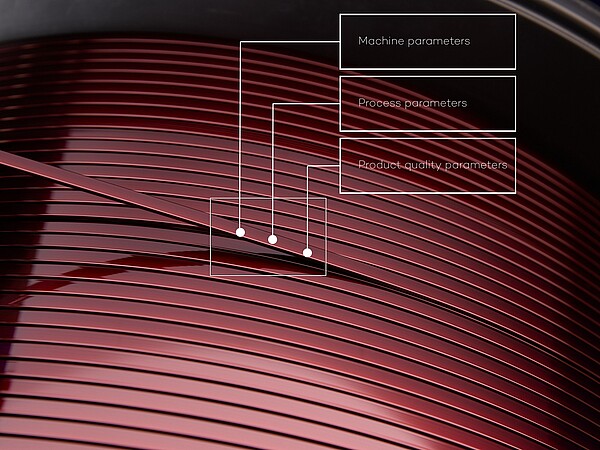

Depth of detail in the wire

Layer structure, material behavior and limit ranges are evaluated under real-world applications - as a basis for resilient decisions.

- Clearer decisions when selecting wire

- Fewer iteration loops in the design

- Greater safety in ramp-up & series production

- Robust performance in real-life use

Interactions in the system

Electrical, thermal, mechanical and chemical influences are considered together - rather than in isolation.

Reproducible results with the Winding Wire Matrix

System expertise needs methodology. With the Winding Wire Matrix and a clear project structure, decisions become comprehensible, reproducible and secure - from the requirement to the release.

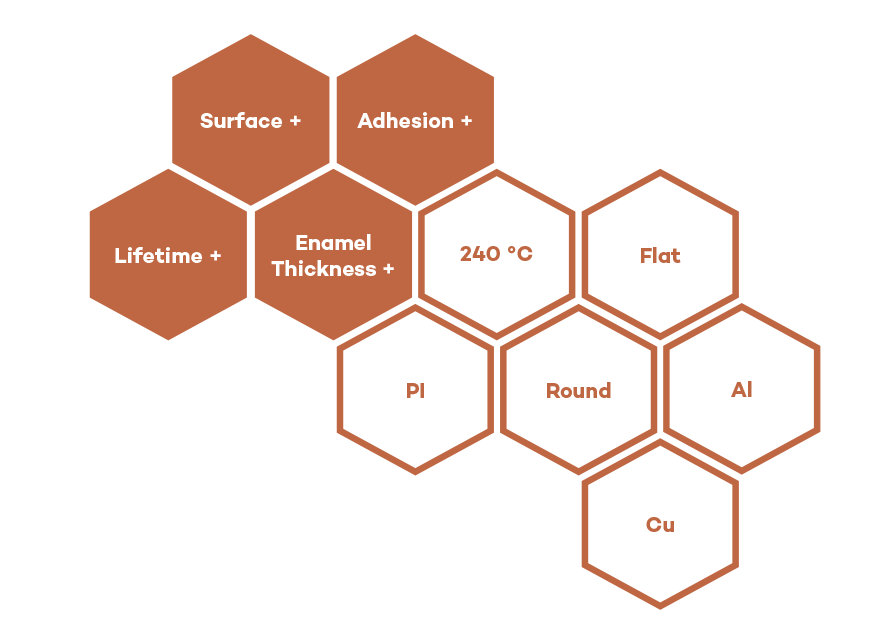

Winding Wire Matrix (WWM)

The Winding Wire Matrix is the key methodological tool. It is used for the structured recording, evaluation and translation of complex customer requirements into concrete product specifications and performance characteristics.

This makes decisions comprehensible, reproducible and reliable for our customers - from the first draft to series production.

IATF-compliant milestones

This methodology is supplemented by IATF-compliant project management with:

- defined milestones

- clear technical approvals

- documented parameter and process corridors

Interfaces that work

Roles, handovers and information flows are clearly defined to ensure consistent decision-making throughout the project.

This makes decisions traceable, reproducible and secure.

From pre-development to series production: system expertise means asking the right questions at every stage, identifying risks at an early stage and designing solutions in such a way that they are sustainable in everyday use.

This seamless support from the "white sheet" to series production ensures a more stable setup and robust series production capability instead of "try & error". Through early analysis, we minimize the effort required for requalifications and offer maximum security for scaling. We support not just one project, but the entire system.

Pre-development

System analysis and design based on electrical, thermal and mechanical requirements.

SOP & Ramp-up

Winding tests, parameter optimization and stabilization under real process conditions.

Evaluation of windability in the interaction of material, process and production.

Series up to EOP

Technical support, process monitoring and continuous optimization throughout the life cycle.

System expertise is visible in the process. This is why product management and application technology provide support where wire works: on the winding machine, in the potting, in the test field and in the ramp-up.

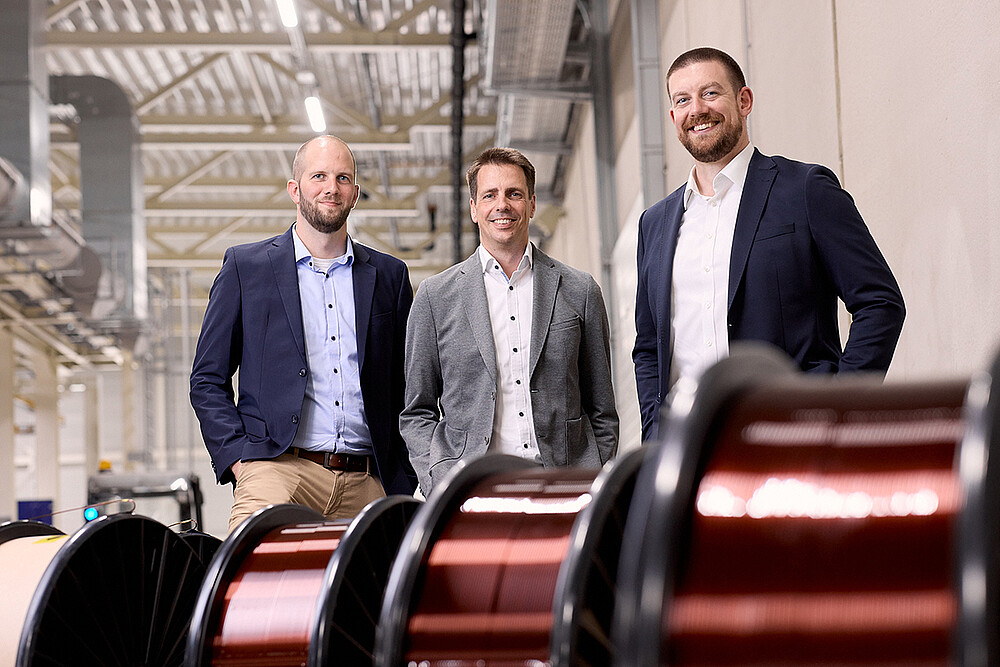

Fabian Radeck, Head of Product Management SHWire

SynFlex Group: We think of the wire as part of the overall electrical insulation system

System expertise means taking an integrated appoach to materials, testing, processes and supply together. As part of the SynFlex Group, the system perspective takes shape along the entire value chain.

Material & system structure

Enameled wires from SHWire combined with insulation materials, adhesive tapes and resins from SynFlex. Conductive and insulating materials are considered as part of a system solution.

Analytics & Tests

Performance tests and UL tests in the SynLab®. Material and performance tests support the design and validation of your application.

Supply Chain & Supply

Security through professional metal management and JIT/JIS delivery. The result: a holistic solution that takes the entire electrical insulation system into account - both technically and logistically.

Get in touch with us!

Whether you have a specific winding task, a high-voltage project or questions about supply chain management - we will put you in touch with the right contact person.

Write to us using the contact form or contact our sales team directly. We will get back to you promptly with a proposal for the next steps.

Email to sales@sh-wire.de Call +49 (0) 5281 9880

- Technical questions (system, innovation, quality)

- Questions about supply chain, availability & conditions

- Strategic projects & long-term partnerships

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

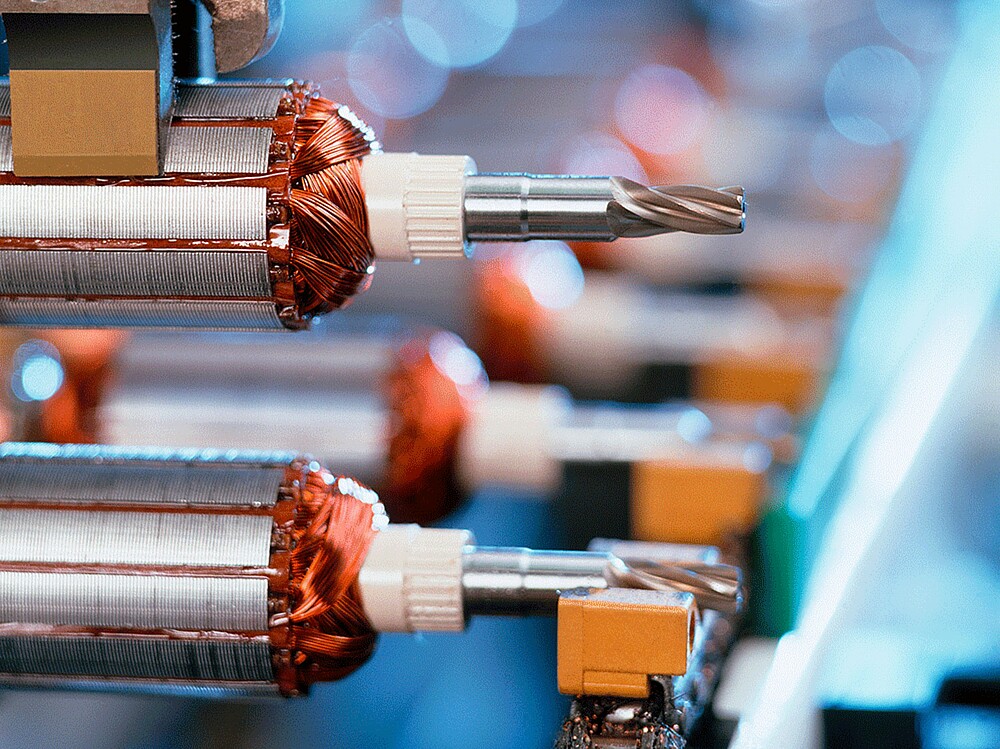

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)