Product quality - intelligence in every centimeter

How can my supplier guarantee that every meter of wire is really in good condition?The importance of quality often only becomes apparent when it is lacking. At SHWire, quality is no coincidence, but the result of a production system. With 100% inline testing as the primary standard, supplementary offline checks, automatic blocking & rejection, full traceability and comprehensive certifications, we supply wire that measurably increases safety, efficiency and service life.

Talk to SHWire about your project

When it comes to enamelled wires, the process determines the performance. Even the smallest deviations during production determine how a wire performs later in the application.

Our quality approach:

Data-first, Industry 4.0+ and experience

Standards such as IEC 60317 define important basic principles - but allow tolerances. These tolerances are often too large for high-speed automation, stable winding processes and reproducible series results. Our approach starts where quality is created: in the process - data-based, automated and supported by the ability to generate real knowledge from data.

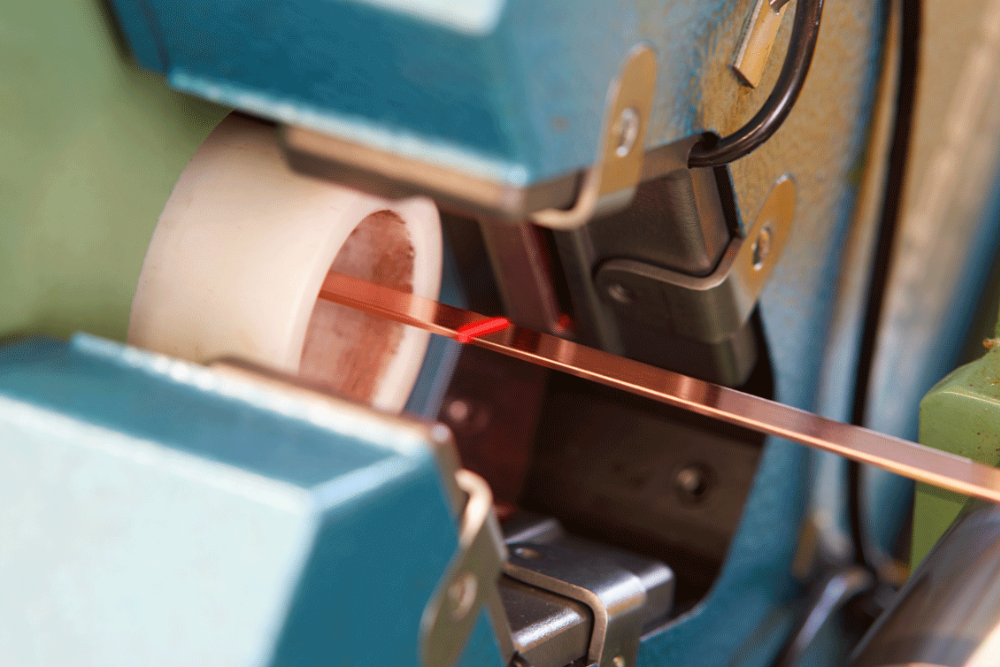

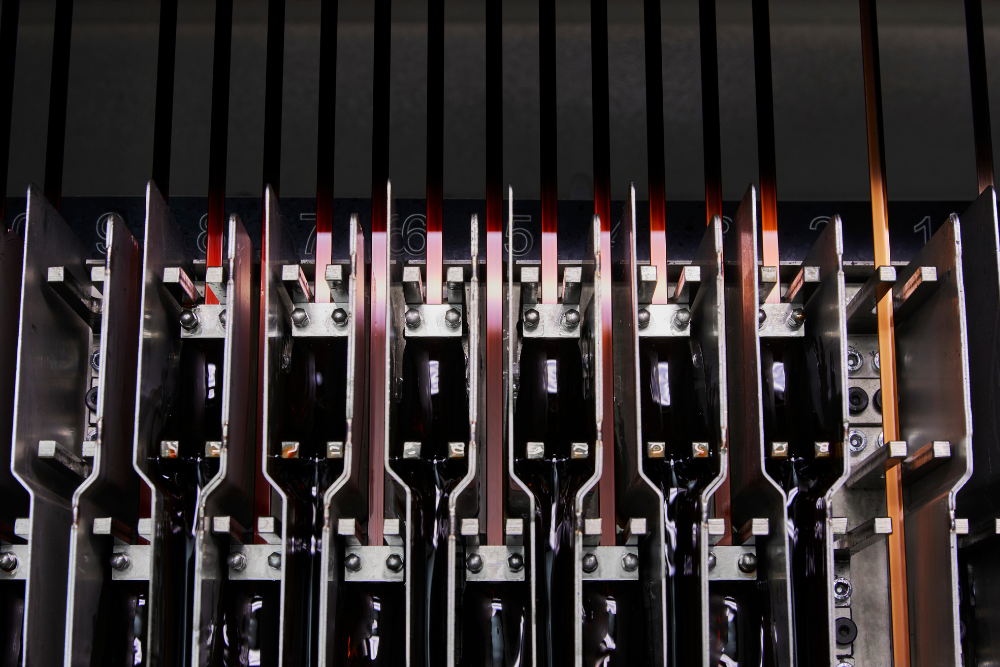

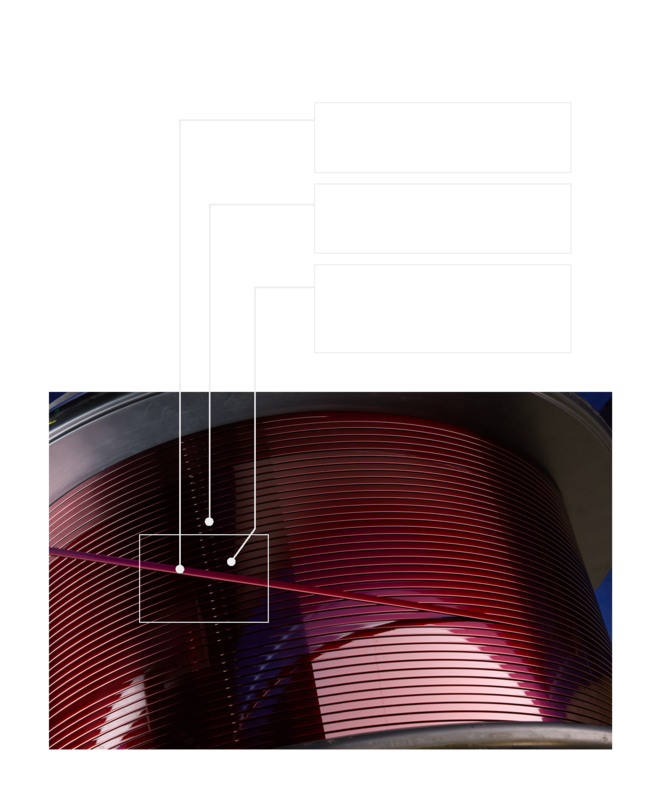

HFZ - High-voltage error count as the basis of our data-first approach

The patented HFZ test is the spearhead of our sensor technology. It measures insulation variations non-destructively and quantitatively throughout the entire production process. HFZ provides reliable quality data beyond binary good/bad statements. In the case of flat wires, this even enables targeted defect marking of faulty segments.

In-line testing as standard

Electrical, optical and geometric inspections monitor every centimeter of enamelled wire - continuously, non-destructively, fully automatically and in real time. A comprehensive set of parameters from machine, process and quality data is continuously recorded across all lines.

Offline testing as a supplement

Elongation at break, varnish adhesion and chemical resistance provide in-depth information that usefully extends inline measurements. This makes them a deliberate addition to our inline signals.

If values deviate from the continuous tests, the affected reel is automatically blocked and rejected. This creates a production flow in which no centimeter remains unchecked.

Our conviction

Stable quality is the result of continuous, data-based, 100% testing, supplemented by targeted laboratory checks by our experts.

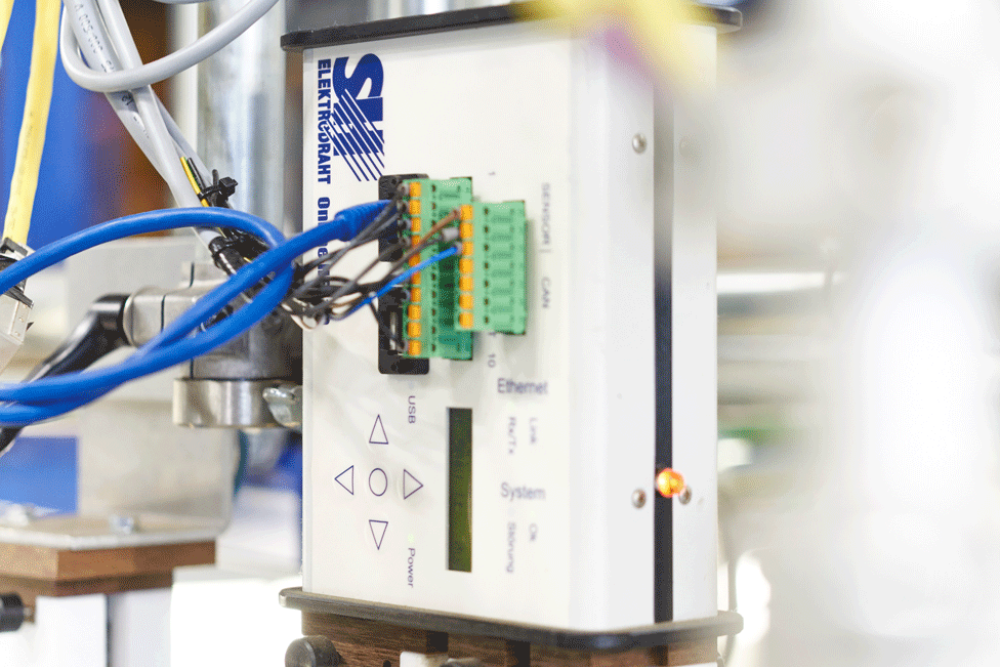

FIT: The heart of our process monitoring

With our FIT production monitoring platform, we network all data streams in real time. FIT recognizes correlations between parameters and independently draws conclusions before deviations become critical. The result: 100% tested enamelled wire - without random samples, without chance.

Core functions of FIT

- Continuous inline monitoring of all critical parameters

- Automatic detection and evaluation of deviations

- Direct initiation of defined measures independent of the operator

- Complete traceability of each reeö via barcode

Future-proof thanks to AI-ready standard

FIT is much more than a monitoring tool - it is our basis for predictive production. Thanks to years of data acquisition, the system is now AI-ready:

- Predictive process control: trend detection before limit values are violated

- AI-Driven: predictive, automated process optimization

- Learning safety: increasing stability with every kilometer produced

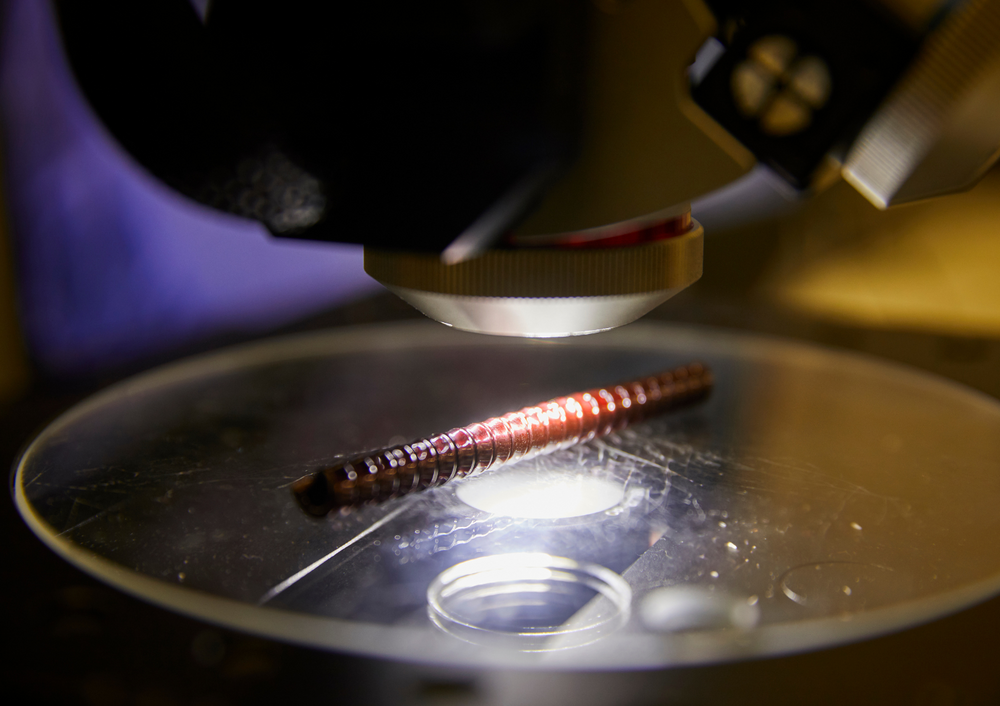

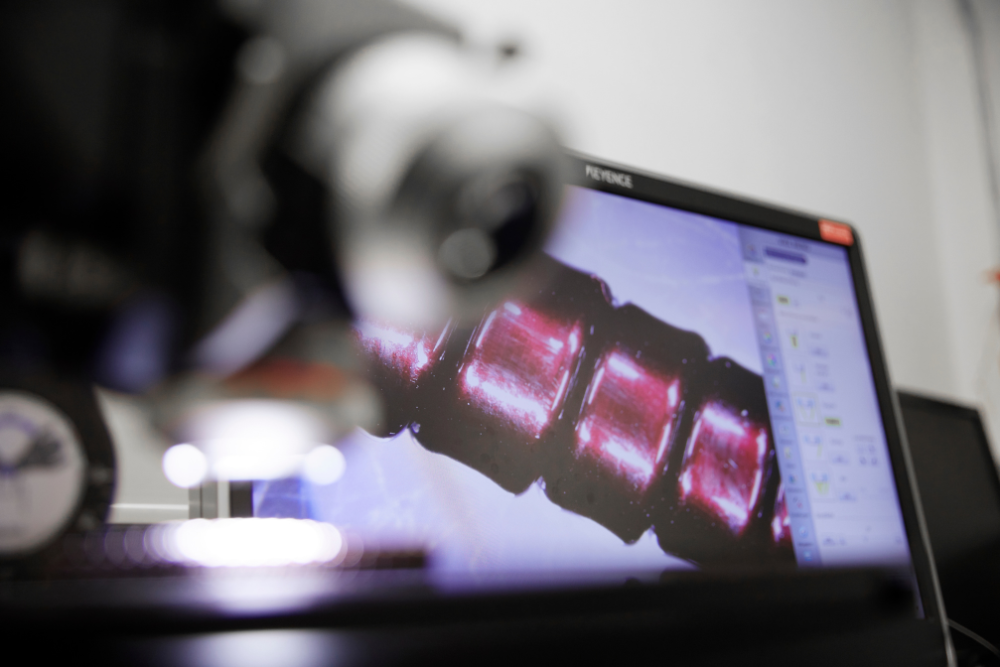

Additional options: SynLab® our in-house laboratory

SynLab® supplements in-line monitoring with in-depth material and coating analyses - especially for applications with high voltages, temperatures or chemical requirements. At the same time, SynLab® is our competence center for research and development: Findings from ongoing production are directly incorporated into coatings and system solutions.

Analytics & Diagnostics

- FTIR spectroscopy and gas chromatography

- Rheology and thermogravimetry (TGA)

- Scanning electron microscopy (SEM)

- In-house PD measuring stand for partial discharge diagnostics

Added value for your projects

- Validation of customer-specific test programs

- Root cause analysis in the event of deviations or test anomalies

- Validation of new varnishes and coating systems (e.g. 800 V+)

What makes our quality verifiable

100%

Inline inspection of every centimeter of enamelled wire

A-supplier

for 100% of customers

175,000 km

tested enamelled wire per day

IATF 16949

among others ISO 9001, TISAX, ISO 45001

Patented

HFZ test method (high frequency high voltage)

Traceability

Complete across all series

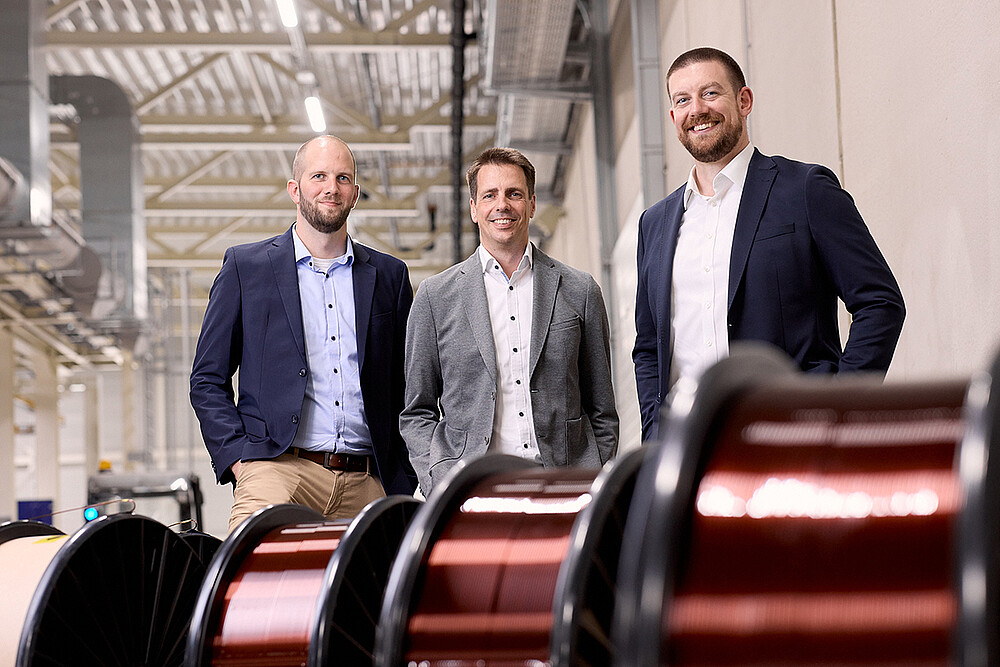

You will not receive a single centimeter of untested wire

Dr. Andreas Levermann, Managing Director SHWire

Get in touch with us!

Whether you have a specific winding task, a high-voltage project or questions about supply chain management - we will put you in touch with the right contact person.

Write to us using the contact form or contact our sales team directly. We will get back to you promptly with a proposal for the next steps.

Email to sales@sh-wire.de Call +49 (0) 5281 9880

- Technical questions (system, innovation, quality)

- Questions about supply chain, availability and conditions

- Strategic projects & long-term partnerships

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)