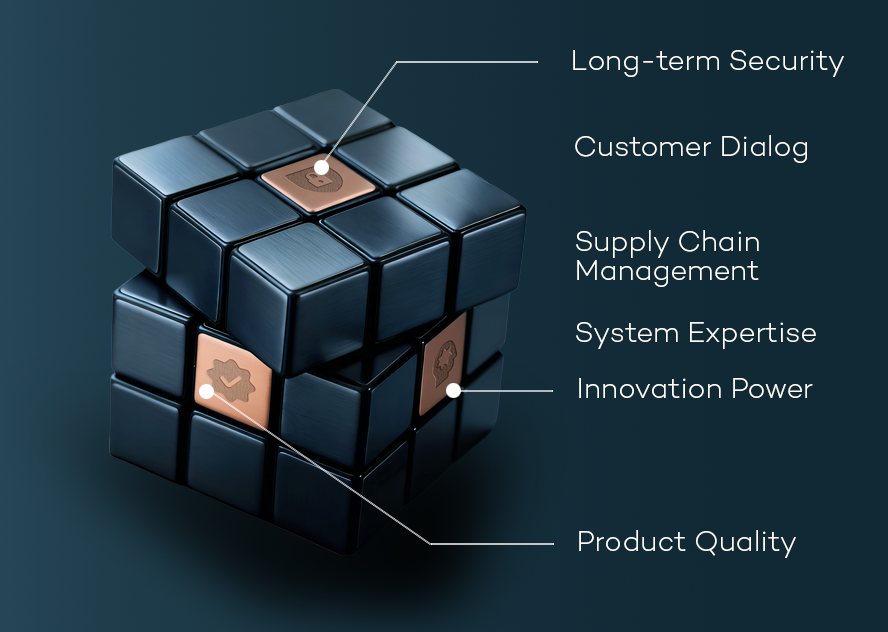

SHWire's Magic for Customer Satisfaction

At SHWire, customer satisfaction is no coincidence, but the result of a system of six dimensions - like the sides of a dice. Our systematic approach makes customer satisfaction reproducible and measurable and provides answers to at least the following questions.

6 questions that move our customers:

-

Product Quality: How can my supplier guarantee that every meter of wire is really in good condition?

-

Customer Dialog: How quickly do I get a reliable answer in case of emergency?

-

System Expertise: Who can help me when I need more than just wire - but rather a solution?

-

Innovation Power: How do I make my applications fit for the latest requirements?

-

Supply-Chain Management: How are metal availability and logistics systemically safeguarded?

-

Long-term Security: How reliable is my supplier in the long term?

Discover the 6 dimensions Contact us directly

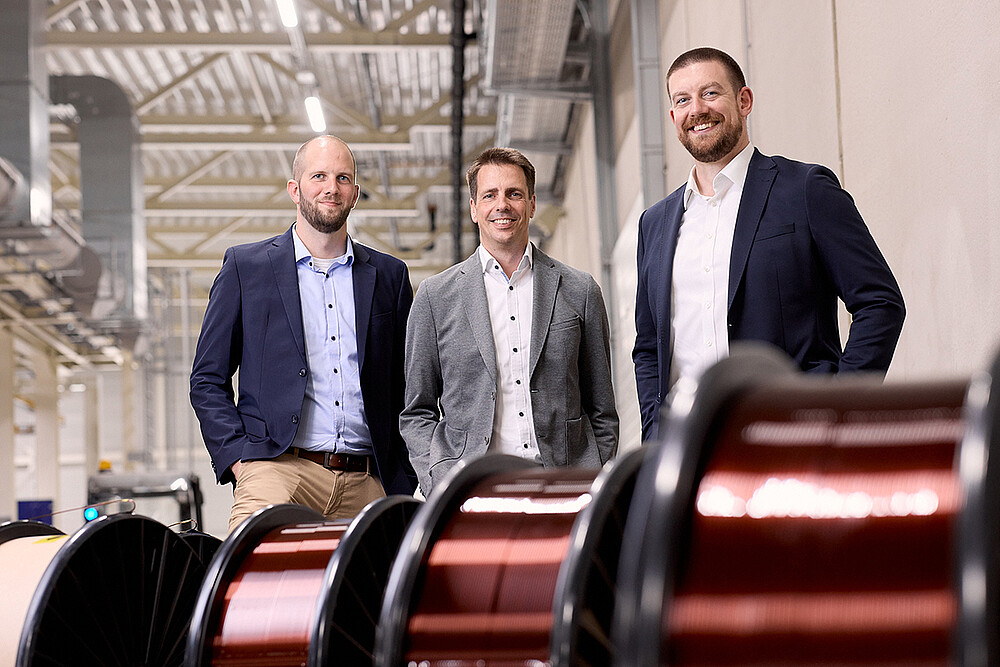

A personal foreword

Our customers keep asking us the same questions: How do I recognize quality early on? How do I remain able to deliver? How do I get quick, reliable answers? Our answer to these questions is not a promise - but a system.

"Long-term, sustainable, trustworthy, innovative - and never at the expense of others. That is SHWire. For five generations."

Constantin Hasse, Managing Partner SHWire

The answer:

A system in six dimensions.

Each dimension answers one of these questions - only their interaction creates customer satisfaction.

Product Quality -

Intelligence in every centimeter

100% in-line inspection, FIT system, HFZ and AI-supported process data ensure reproducible quality in every millimeter of wire.

→ Because you expect quality that prevents defects from occurring in the first place.

Innovation Power -

Progress in every solution

In-house coating chemistry, customized development and DoE methodology. Innovations - from SHGlide and SHXLife® to SHTherm® 240 PI - also for you.

→ Because you rightly demand product & process innovations.

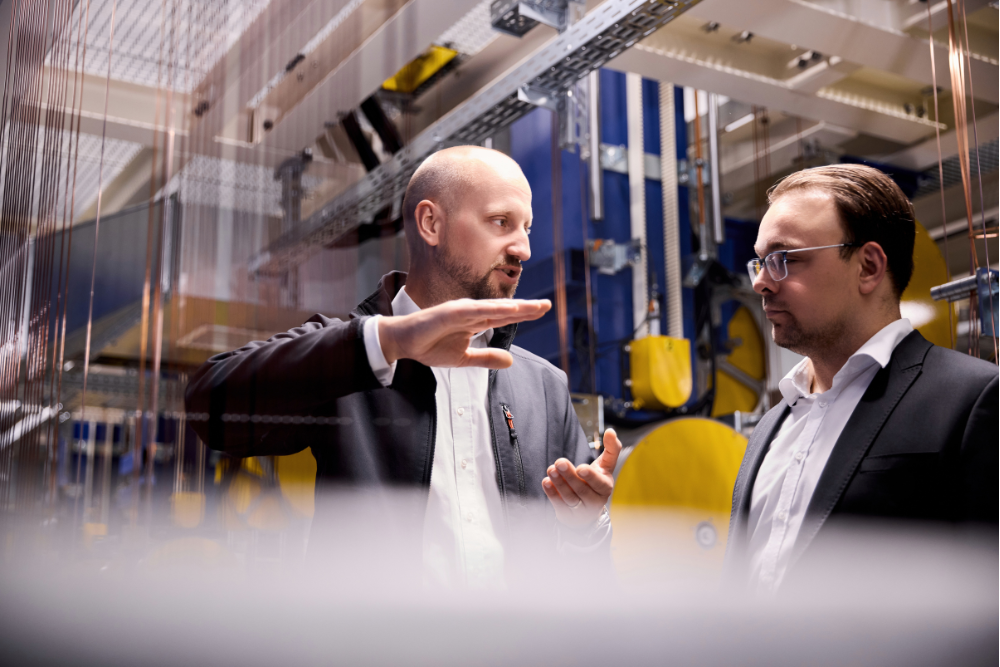

Customer Dialog -

Commitment in every word

Clear responsibilities and an end-to-end support process ensure that decisions are made consistently from your perspective.

→ Because you expect communication that speeds up decisions - not complicates them.

Supply-Chain Management-

More in every dimension

An integrated supply system: metal management, beat your budget, high-performance logistics and individualization work together in one system.

→ Because you expect reliable supplies and predictable costs in every market situation.

System Competence -

Solution in every step

The depth of detail in the wire, WWM-supported selection and strategic product management provide you with a wire solution that really fits your application.

→ Because you need partners who know the details and the system.

Long-term Security -

Reliability in every generation

Family business in its 5th generation, certified systems, cross-generational responsibility and consistent further development.

→ Because you don't want to miss out on stability as a competitive advantage for years to come.

When systematics are convincing - results that count.

Reliability that can be proven

Results count. That's why we make the impact of our system measurable - in kilometers, key figures and ratings.

100 % in-line inspection

Every centimeter of flat wire is monitored in real time - including FIT system, HFZ and full traceability.

175,000 km per day

Europe's largest single location for enameled wire: high capacities, stable processes and reproducible quality in series production.

>21,000 pallet spaces

Fully automated high-bay warehouse, poka-yoke process design and end-to-end ERP integration secure the supply chain.

100 % communication rating

In supplier evaluations, we consistently achieve top marks in the "Communication" criterion, among others - an expression of our understanding of customer dialog.

Get in touch with us!

Whether you have a specific winding task, a high-voltage project or questions about supply chain management - we will put you in touch with the right contact person.

Write to us using the contact form or contact our sales team directly. We will get back to you promptly with a proposal for the next steps.

Email to sales@sh-wire.de Call +49 (0) 5281 9880

- Technical questions (system, innovation, quality)

- Questions about supply chain, availability and conditions

- Strategic projects & long-term partnerships

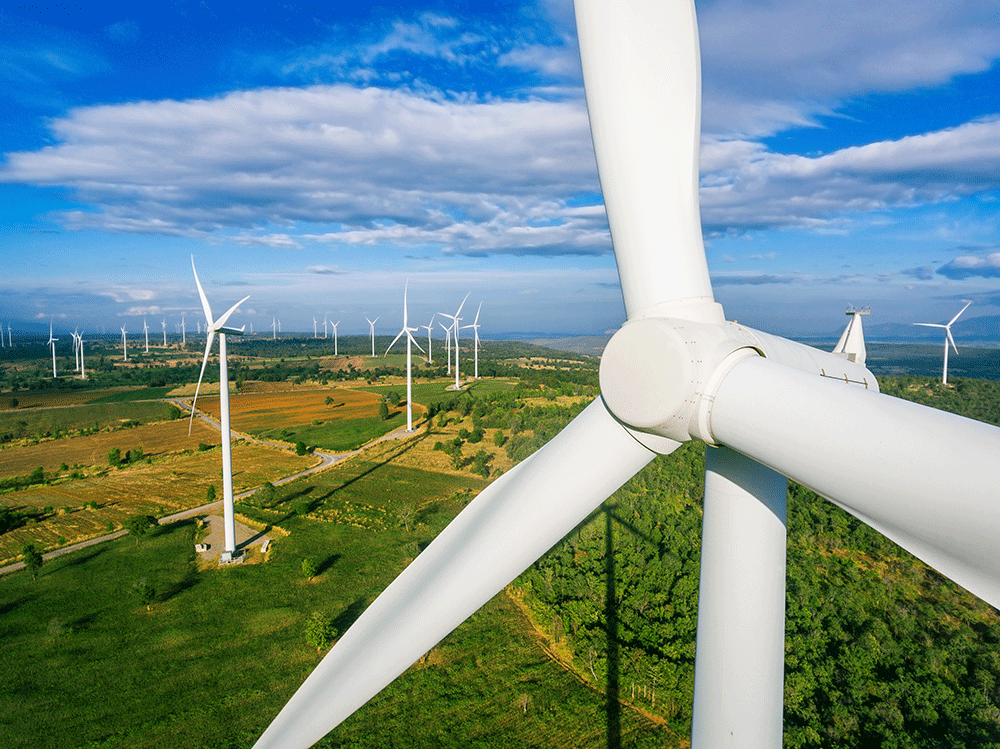

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)