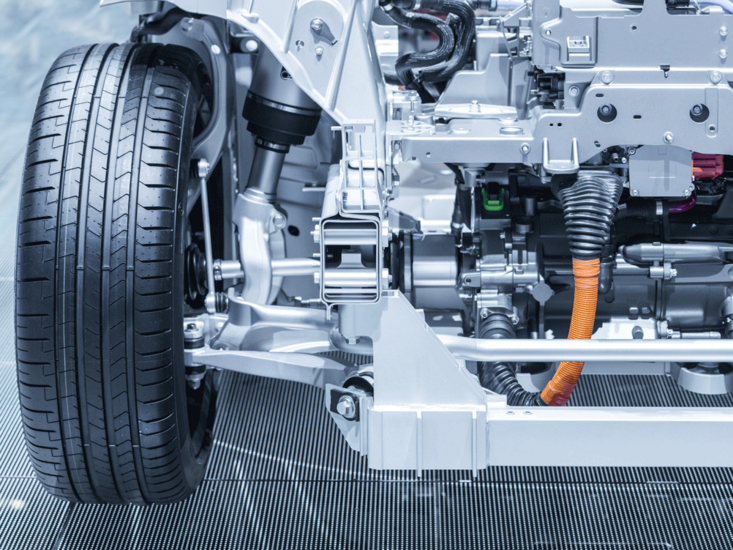

Technology and quality leadership in e-mobility

SHWire is one of the technology leaders in the development of enamelled copper wires for electromobility. For over a decade, we have been supplying wire solutions for electric drives – from ancillary unit applications to high-voltage traction motors – and we set standards for quality, safety and performance. With many years of experience in large-scale automotive production and a deep understanding of applications, we are actively shaping technological developments.

Progress in series production: How SHWire turns innovation into reality

As a pioneer and development partner in electrified drive technology, SHWire tackles challenges with one clear objective: to lead the way in innovation with solutions that are ready for serial production.

We work closely with customers and market partners to identify new requirements at an early stage and develop concrete solutions based on these findings. Our research and development department specializes in turning these findings into production-ready innovations.

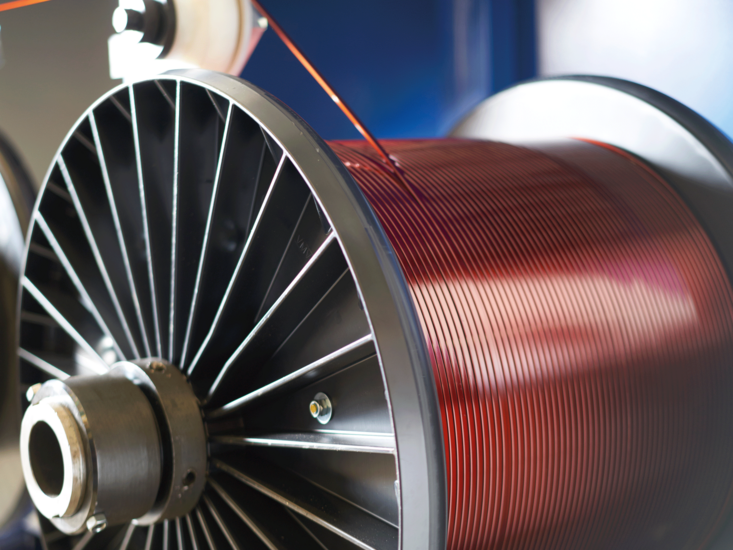

The SHXLife® series represents a new generation of enamelled copper wires offering a significantly longer service life in partial discharge conditions. A specially developed enamel system containing functional additives provides particularly resistant insulation structure.

This opens up new possibilities in motor design, with higher winding density and an increased copper fill factor ensuring greater efficiency and cost-effectiveness. SHXLife® is therefore the ideal solution for modern 800 V+ traction applications, being ready for series production, cost-efficient and in line with the SHWire Industry 4.0+ standard for inline monitoring.

Our high-performance SHTherm® series wires, including PI-coated variants such as the SHTherm® 240 PI Flat, offer maximum thermal and electrical capacity. Designed for use in traction motors in the automotive high-voltage sector, they provide optimal insulation safety, even in extreme conditions.

They are the ideal solution when the highest levels of safety, voltage and temperature resistance are required.

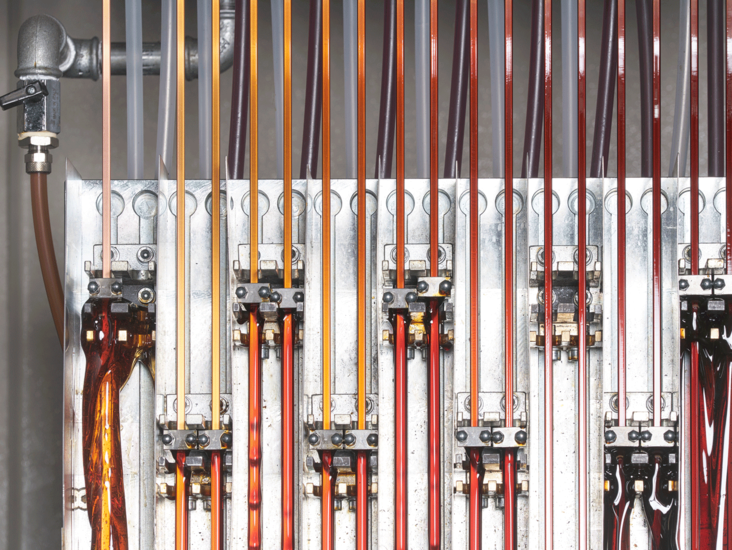

Certified quality for high-voltage applications

Our copper and aluminium enamelled wires meet the highest quality standards. We monitor production using our patented system which goes far beyond industry standards. Fully automated checks are carried out continuously throughout the entire production process, enabling us to intervene quickly in the event of irregularities. This allows us to guarantee the highest quality of our enamelled copper and aluminium wires, setting benchmarks for Industry 4.0+ in enamelled wire production with our innovative process monitoring.

We further improve our quality levels through regular audits, during which we optimize our internal processes and procedures. In doing so, we focus not only on our products, internal processes and procedures, but also on our customers. Our IATF 16949 certification demonstrates that we consistently meet the stringent quality, product safety and legal compliance requirements throughout the entire supply chain. If you are a customer in need of innovative enamelled copper wires, you will clearly benefit from this.

Our Enamelled Copper Wires for E-Mobility

SHTherm® 210 Flat

- High-temperature-resistant flat enamelled copper wire, thermal class N

- Excellent thermal endurance and overload capacity

- Outstanding resistance to mechanical stress

- Excellent insulation properties

SHTherm® 240 PI Flat

- High-performance flat wire with polyimide coating for the most demanding requirements

- Maximum thermal and electrical insulation resistance

- Ideal for demanding traction applications in the high-voltage range (800V+)

SHXLife® 220 Flat

- Enamelled wire-based solution for significantly extending service life under partial discharge

- Increased winding density thanks to reduced layer thickness

- High efficiency and cost-effectiveness for 800V+ applications

SHXLife® 240 PI Flat

- Combines partial discharge tolerance with maximum thermal stability

- Polyimide-coated high-performance wire for maximum design reliability

- Ideal for 800V+ applications

Our development team will be happy to assist you with your projects. In addition to standard wires we also offer wires that are adjusted to your requirements. That way we jointly advance innovations in e-mobility. Contact us at any time.

High-performance enamelled copper wire for 800V+ e-mobility solutions

New SHXLife enamelled copper wire offers:

- New SHXLife enamelled copper wire offers:

- Durability: 500x life time* under partial discharge

- Design flexibility: Enables smaller safety margins

- Increased efficiency: Increased copper fill factor due to reduced layer thicknesses

- Economy: Makes 800V+ solutions more cost-effective

- Excellent quality: Manufactured according to recognized SHWire 'Industry 4.0+' process technology

Thanks to a unique combination of materials in the coating system, the limits of service life under partial discharge have been shifted for the first time into areas that make it possible to allow partial discharge in the design. This opens up unprecedented options in the design of electric motors in the 800V+ environment.

Our Know-how – Your Benefits

- More than 70 years of experience in enamelled wire production

- Certified to IATF 16949:2016

- Patented SHWire quality monitoring, far above industry standard

- Numerous innovations already in series productio

Are you interested?

The standard for QM systems in the automotive industry IATF 16949:2016 defines the sector-specific requirements for series and spare parts production based on DIN EN ISO 9001:2015.

In the course of the annual certification SHWire has successfully passed the surveillance audit by the certification company DQS. For this purpose, processes of the QM system are continuously questioned, monitored, evaluated and optimized by the employees. Customer satisfaction is optimized by the continuous improvement of system and process quality. This enables us to meet the increasing demands on product quality, productivity and competitiveness and also to increase the performance for our customers.

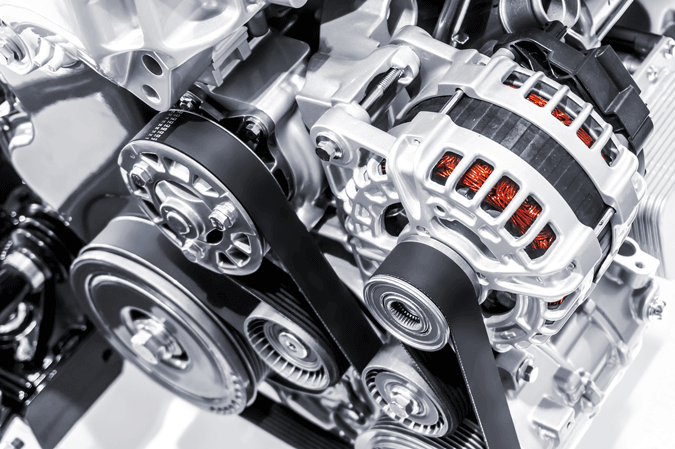

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)