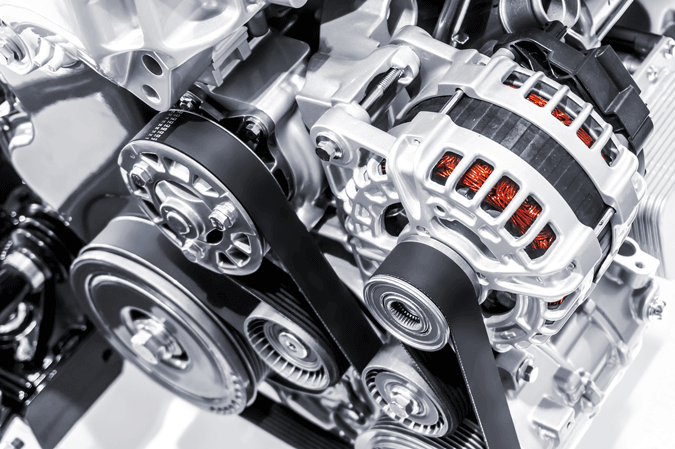

Drive Technology - we make the World move

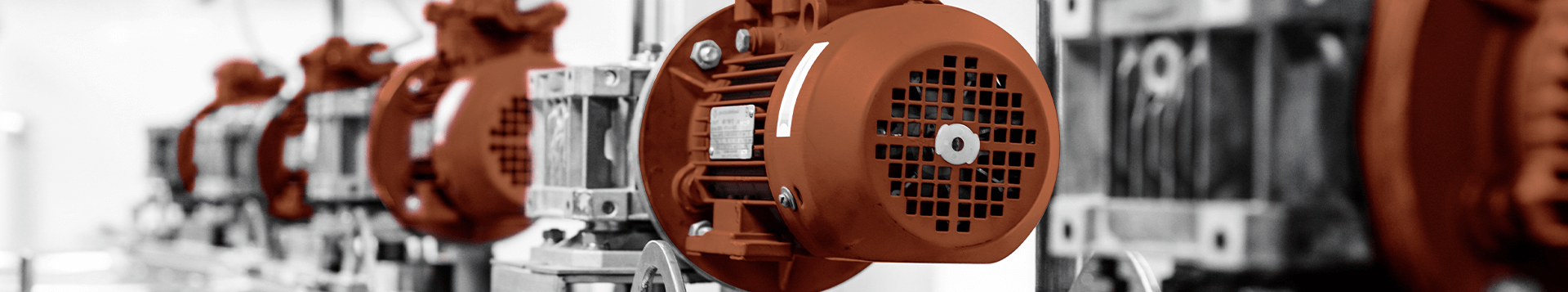

If motion is generated with the aid of an electric motor, this is referred to as electrical drive technology. Countless inverter-controlled electric motors in industrial and conveyor systems ensure that conveyor belts and production lines do never stand still.

Decades of experience in drive and automation technology make us a partner to leading companies in the industry. Our enamelled copper wire enables the construction of efficient motors and conveyor systems and is tailored to the requirements of drive technology. Even if you need special wires for your project, you can rely on us.

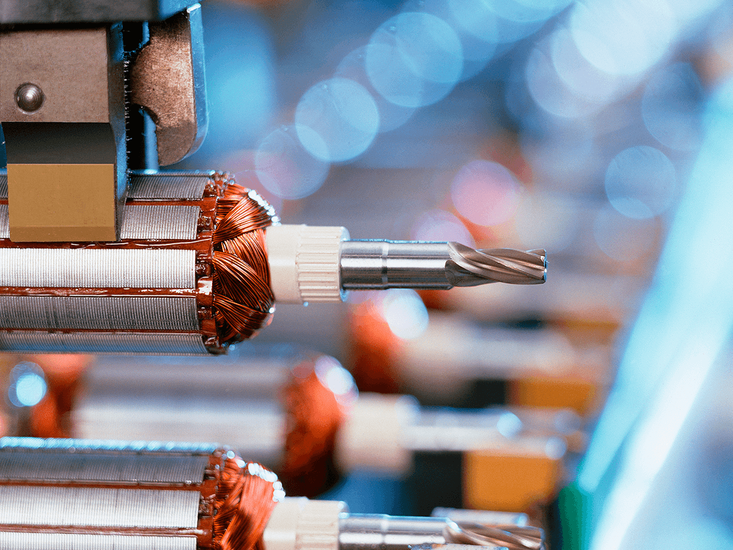

Enamelled Wires of certified Quality

Our enamelled copper and aluminium wires meet the highest quality standards and our innovative process monitoring sets benchmarks for Industry 4.0+ in the production of enamelled wires. Thanks to continuous and fully automated checks throughout the entire production process, we can quickly intervene to correct any irregularities. Our patented system goes well beyond the industry standard.

In regular audits, we optimize internal processes and procedures and constantly increase our quality level. In addition to our products, we also keep an eye on our customers. We meet consistently high requirements for quality, product safety and legal compliance throughout the entire supply chain and are certified in accordance with IATF 16949. A clear benefit for you as a customer with demand for innovative enamelled copper wires.

Our enamelled wires for drive technology

- extended service life

- partial discharge resistant

- optimized fill factor

- thermally and mechanically robust

- suitable for 800V+ systems

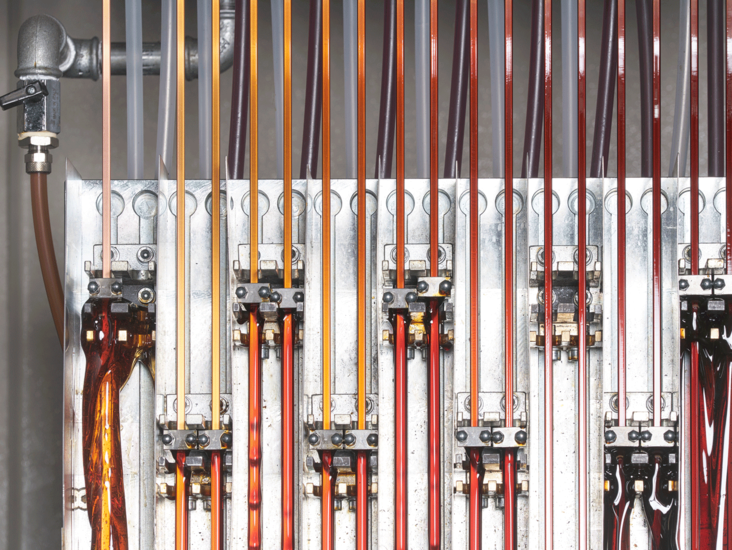

SHTherm® 210

- High temperature resistant enamelled copper wire,

round, temperature class N - Excellent mechanical resistance to abrasion

- Extremely low coefficient of friction for gentle

wire processing - Verifiably improved strength of insulation

SHTherm® 210 Glide

- High temperature resistant enamelled copper wire, round, temperature class N

- Low friction functional coat for excellent windability at optimized winding speed

- Reduced machine contamination and lower mechanical stress during winding process

- Gentle wire processing due to reduction coefficient of friction

SHXLife® 220 Round – Designed for maximum reliability in continuous industrial use

Industrial drive systems depend on maximum reliability under continuously high loads – even under difficult environmental conditions. With SHXLife® 220 Round, SHWire offers an innovative round wire solution that has been specially developed for these requirements:

The optimized coating system forms a hard-wearing, partial discharge-resistant protective layer that significantly extends the service life of electrical windings – even under constant stress from voltage peaks, temperature changes and vibrations.

SHXLife® not only enables a service life over 500 times longer than standard polymers, but also allows for more compact winding geometries thanks to higher copper fill factors. This is a significant advantage for ensuring the efficiency, robustness and low maintenance of drive systems in continuous industrial operation.

Our Know-how - Your Benefits

- More than 70 years of know-how in the production of enamelled wire

- Recognized innovation leader in the industry

- High-performance products for special requirements

- Customer-specific new developments

The standard for QM systems in the automotive industry IATF 16949:2016 defines the sector-specific requirements for series and spare parts production based on DIN EN ISO 9001:2015.

In the course of the annual certification SHWire has successfully passed the surveillance audit by the certification company DQS. For this purpose, processes of the QM system are continuously questioned, monitored, evaluated and optimized by the employees. Customer satisfaction is optimized by the continuous improvement of system and process quality. This enables us to meet the increasing demands on product quality, productivity and competitiveness and also to increase the performance for our customers.

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)