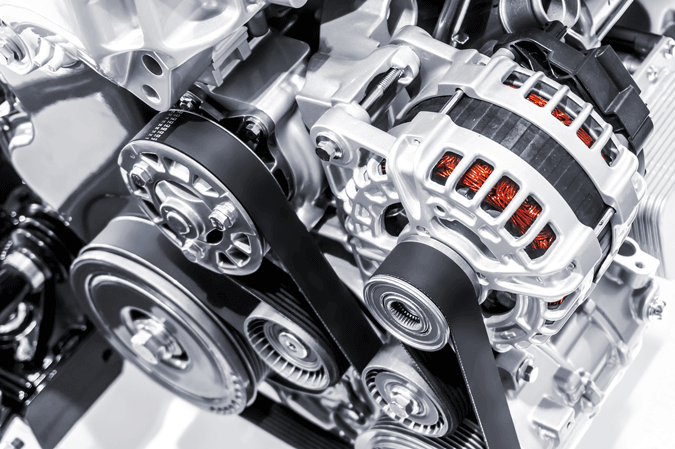

Premium winding wires for the automotive industry

Enamelled copper and aluminium wires are essential components of automotive electrical systems, significantly contributing to their safety, efficiency and reliability. SHWire offers solutions for almost all applications in automotive winding technology, ranging from classic auxiliary motors to high-load traction applications. Our portfolio of enamelled wires meets the highest standards of temperature resistance, mechanical strength, chemical resistance, and electrical insulation properties.

We work with renowned automotive manufacturers because the industry values us for the quality of our innovative products. Decades of collaboration have given us comprehensive application expertise in the automotive sector.

Innovative Enamelled Wires for the Automobile Industry

Our research and development team is constantly working on innovative wire solutions that are tailored to the specific requirements of the automotive industry, often in close collaboration with our customers. The result is products that set new standards in terms of performance, service life and efficiency.

For example, PI-coated flat wires (SHTherm® 240 PI Flat) are available for automotive applications, requiring maximum temperature and voltage resistance, such as in the high-voltage traction sector. Designed for maximum safety, they meet the highest requirements for thermal, electrical and chemical resistance.

The SHXLife® 220 Round series is a pioneering wire technology for automotive applications involving round wires, such as actuators, sensors and auxiliary motors. Thanks to its innovative insulation concept, it achieves an exceptionally long service life, even under partial discharge, making it particularly well-suited for continuous industrial use.

Meanwhile, classic solderable wires such as the SHSold® V180 and universal wires from the SHTherm® 210 series remain important for robust, economical solutions for low voltage applications.

Our enamelled copper wires for your automotive application

SHTherm® 210

- High temperature resistant enamelled copper wire,

round, temperature class N - Excellent mechanical resistance to abrasion

- Extremely low coefficient of friction for gentle

wire processing - Verifiably improved strength of insulation

SHTherm® 220

- High-temperature-resistant round enameled copper wire of thermal class R

- Excellent thermal and chemical resistance

- Safety in electrical insulation

- Winding density after highly demanding winding, insertion, and forming processes

SHSold® V180

- Fast and directly tin-plated copper enameled wire of thermal class H

- High continuous heat resistance and thermal strength under short-term loads

- High ductility, easy formability, and excellent insulation properties

- PI-coated flat wire for high-voltage traction applications

- Highest thermal, electrical and chemical resistance

- Maximum safety in extreme operating conditions

- Innovative insulation structure for long service life even under partial discharge

- Suitable for actuators, sensors and auxiliary motors in automotive environments

- Robust performance in continuous industrial use

In addition to our standard products, our development team is happy to work with you on projects to tailor our wire to your needs. This is how we jointly drive innovation forward. Feel free to contact us for development projects.

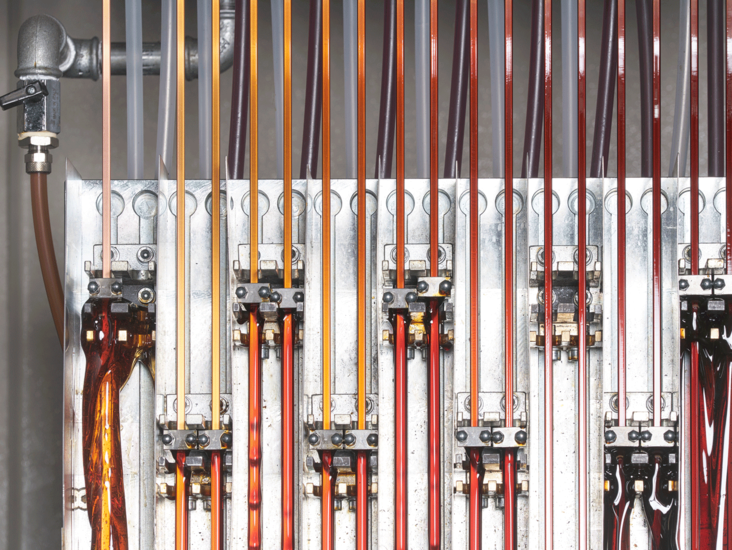

Production Monitoring and Certifications

We are well-known in the industry for highest quality enamelled wires. Our products received several awards. Our patented production monitoring system is subject to much stricter criteria than customary in the industry and ensures consistent quality. Throughout the entire production process, all operating and machine data is permanently recorded fully automatically for each machine and production line. In this way we can measure, control, document and store all process and production parameters without interruption - and intervene if necessary. With this innovative process monitoring system, we are setting standards for Industry 4.0+ in enameled wire production.

Through regular audits of certification companies and customers, in which we optimize our processes and procedures, we further increase our quality level. Certification to IATF 16949 is evidence that we meet the high standards of quality, product safety and legal compliance throughout the entire supply chain. This is your benefit as a customer with demand for innovative enamelled copper wires

Our Know-how – Your Benefits

- More than 70 years of experience in enamelled wire production

- Certified to IATF 16949:2016

- Comprehensive product and application know-how based on decades of experience as a supplier to the automotive industry

- Patented SHWire quality monitoring, far above industry standard

Are you interested?

The standard for QM systems in the automotive industry IATF 16949:2016 defines the sector-specific requirements for series and spare parts production based on DIN EN ISO 9001:2015.

In the course of the annual certification SHWire has successfully passed the surveillance audit by the certification company DQS. For this purpose, processes of the QM system are continuously questioned, monitored, evaluated and optimized by the employees. Customer satisfaction is optimized by the continuous improvement of system and process quality. This enables us to meet the increasing demands on product quality, productivity and competitiveness and also to increase the performance for our customers.

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)

![[Translate to Englisch:] Automotive](/fileadmin/user_upload/Soft_Relaunch/SHW_HP_Header_Automotive.png)