The history of characterising and comparing materials goes back a long way. Technological development occurred parallel to the creation of new materials and the new processes, and methods for testing and analysing the properties associated with them. This process is continuing at a breath-taking pace.

Employing the latest procedures, we at SynLab® develop and test all materials used in the winding industry – promptly, flexibly, individually and innovatively. Moreover, the SynFlex lab also evaluates electrical insulation systems pursuant to strict UL criteria to ascertain their suitability for use in a variety of areas. These applications include drive technology, the automotive industry, rail transport and energy generation and distribution.

SynLab® tests, documents and assesses the materials of tomorrow for customers all over the world. A prerequisite for every examination and development in this area is material characterisation, which forms the basis for all further decisions. At our location in Lügde, a scanning electron microscope is available for conducting these investigations.

Qualitative and quantitative analyses of surfaces with regard to topographic quality can be realised to the highest definition with the aid of the scanning electron microscope (SEM). In addition, a clear statement regarding the materials contained in a sample can be made using the SEM station. Minuscule quantities of chemical elements can be verified by the SEM.

SynLab® therefore offers the chance to identify materials provided by customers. Different samples can be accurately compared with each other and the differences illustrated. One frequent application in the winding industry is the analysis of contamination or even adhering substances. The scanning electron microscope ultimately offers the possibility to conduct analyses for defective parts which allow conclusions to be drawn about the cause of material damage.

SynLab® combines the technical equipment and know-how of our specialists with an in-depth understanding of winding industry requirements and the complexity of electrical insulation systems. The demands made upon materials and systems continue to grow. These can only be met if one remains innovative and open to development. The options offered by SynLab® test laboratories in Europe and Asia mean that a reliable partner exists ready to meet these demands.

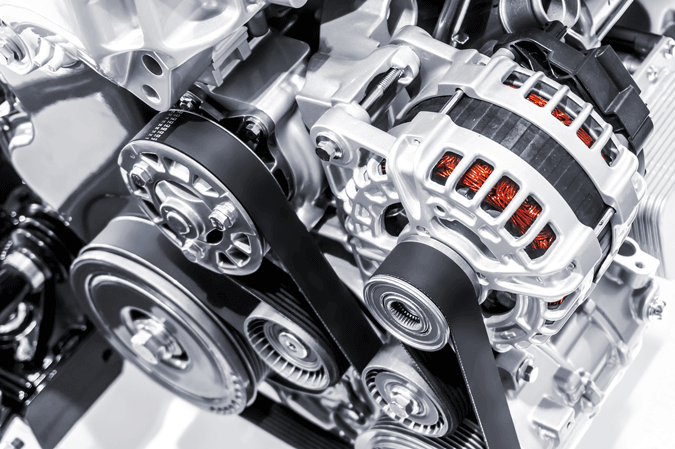

![[Translate to Englisch:] Antriebstechnik](/fileadmin/_processed_/2/3/csm_shutterstock_1139710454_d7b2a7b72f.png)

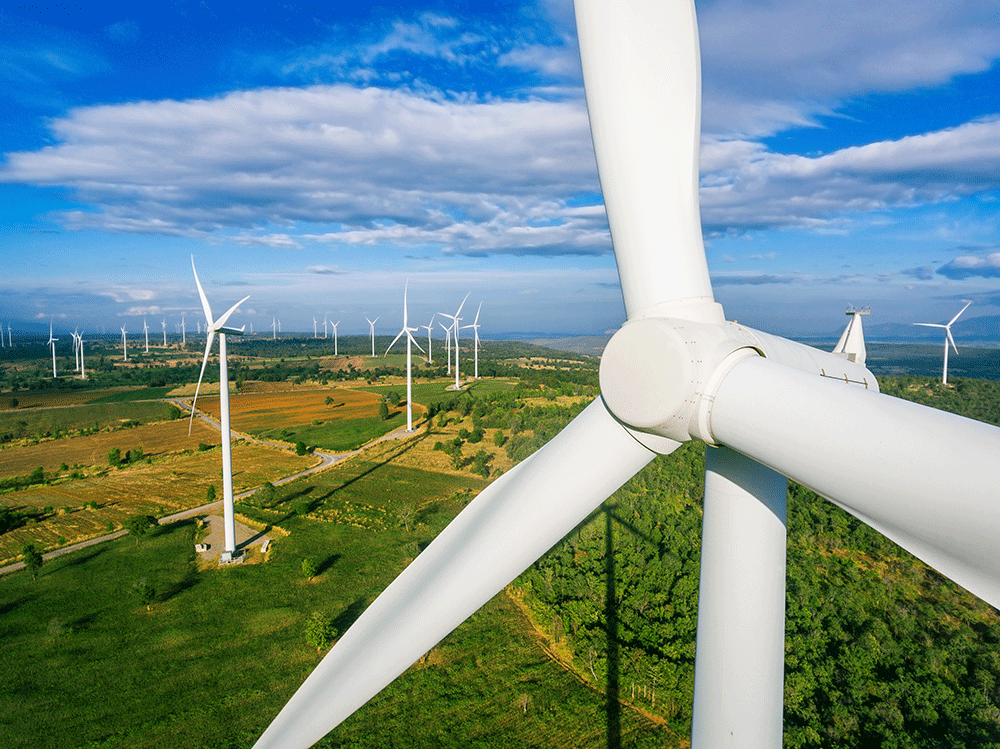

![[Translate to Englisch:] Energieübertragung](/fileadmin/_processed_/b/2/csm_shutterstock_774593137_59871ac3b6.png)